At Cadet, we have been manufacturing heaters for over 59 years here in the Pacific Northwest. During this time, we have grown, changed and learned much in being a community partner. As we have grown, there are some things that have remained constant. The value we have for our employees, the respect we have for our partners, the engagement with our community and the sustainable practices we have implemented.

Several years ago, Cadet formed a cross-department “Green Team” to look at how our business, people and processes could further reduce our footprint and impact on the environment. Since 2007, we’ve reduced the amount of material we send to landfills by 75%. Additionally, we are seeing employee engagement throughout our company. Here are a few highlights of our accomplishments:

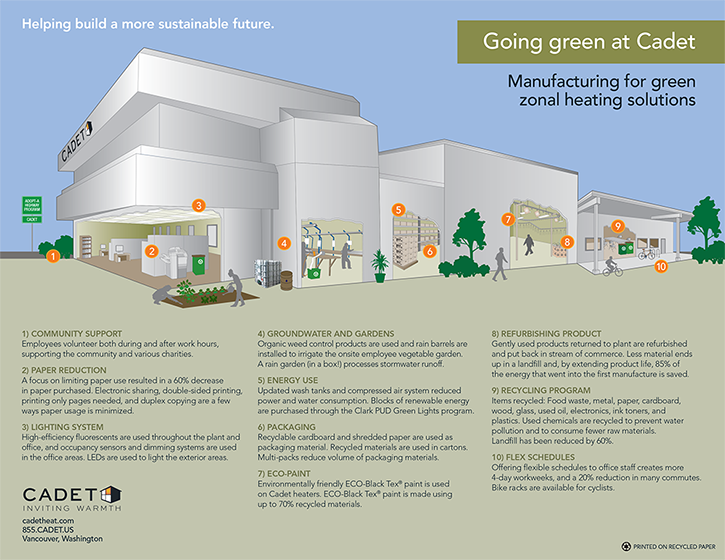

- High-efficiency LEDs are used throughout the facility and outside the building. Occupancy sensors and dimming systems are used in the office areas as well.

- Cadet employees volunteered a total of 1,410 hours throughout 2015. Employees can volunteer both during and after work hours, supporting the community and various charities.

- In our office, we have decreased our paper usage by 60%. Employees focused on limiting paper use by sharing documents electronically, using double-sided printing and only printing when completely necessary.

- We utilize rain barrels, collecting water that is then used for landscaping and for our employee vegetable garden. A grattix rain garden box cleans storm water from the plant roof before sending it into the storm drain.

- We updated our wash tanks in our paint shop to reduce water consumption and the compressed air system in the plant.

- We redesigned product packaging and now use recyclable cardboard as well as shredded paper. We also ship in multi-packs to reduce the volume of packaging materials needed.

- Our paint is now made of up to 70% recycled materials.

- Gently used products are returned to our plant and refurbished. Thus reducing the amount of material ending up in our landfills. 85% of the energy that went into building the heater the first time is saved.

- Cadet offers flexible schedules to employees with 4-day workweeks. This creates a 20% reduction in many commutes. Bike racks are also available for cyclists.

In 2015 we noticed that a large percentage of our landfill waste was film plastics, which were no longer being collected by our local recycling company. We began collecting these materials to recycle them ourselves. These plastics being recycled, are now turned into composite wood materials. With this change we expect to eliminate 3000 pounds from our landfill.

We are proud of our employees, proud of our sustainable efforts and proud to be a Pacific Northwest manufacturer that continually works to improve not only our company, but the impact we have in our community.

To learn more about who we are, what we do and our products, please visit our site;

Cadet.