Earth Advantage inspects all areas of the thermal envelope to confirm the quality of the insulation installation. This is one of the first items on the

Thermal Enclosure Checklist (TEC), which is required for all homes pursuing Earth Advantage Certification.

Item 2.2 on the TEC states, “All ceiling, wall, floor, and slab insulation shall achieve RESNET-defined Grade I installation..” In exterior wall cavities, EA field inspectors are verifying the “six-sided box rule” – which is the insulation must fill each cavity side-to-side, top-to-bottom, and front-to-back with

very minimal gaps, cracks, and voids. (See the full definition of Resnet Grade I

here, Appendix A, page A-11)

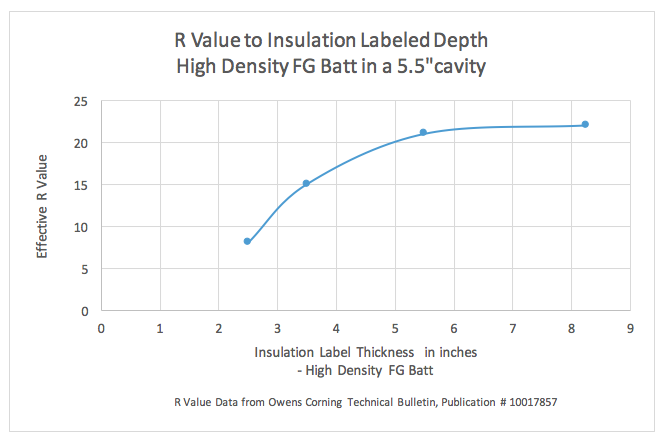

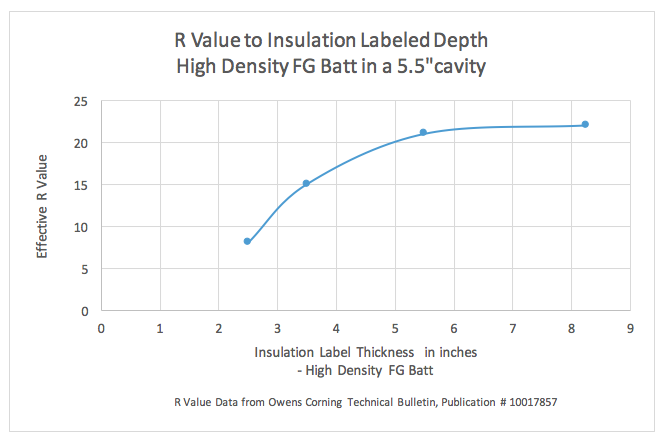

In small cavities - such as “California corners” and other framing cavities less than 3” wide, where blown-in insulation typically does a poor job achieving the correct density due to back pressure – fiberglass batts are frequently installed instead. The batt cannot effectively be “fluffed” to its intended thickness in small cavities and be in contact with all six sides due to friction from the adjacent framing members. In this instance, we require that insulation completely fill the cavity, even if some compression of the insulation is required to do so. As the graph below shows, compressing fiberglass batts in a wall cavity has

no detrimental effect on the effective R value of the insulation - as long as additional insulation is installed to completely fill the cavity.

The first two plot points represent the lower R value achieved with a stud cavity that is incompletely filled with a batt, while the third point reflects the R value using an R 21 batt, correctly installed in contact with all sides of a 5.5” stud cavity. The fourth plot point, at R 22, shows the effective R value of an 8.25” thick R 30 batt, compressed into a 2X6 stud cavity.

As the data above shows, compressing the fiberglass batt insulation with additional batts in order to fill the wall cavity has a negligibly positive effect on the performance compared to a correctly sized batt, fluffed to completely fill the wall cavity.

Most importantly, completely filling all wall cavities allows the envelope to achieve the intended R value -- and comply with the Thermal Enclosure Checklist.

* Below grade masonry walls and some LEED projects are an exception – they do not require a full wall cavity fill. The insulation must be in contact with the “primary” air barrier on the rare project where the wall cavity is not specified to be completely filled.